Welding is a common industrial process that involves joining two or more metal parts. Historically, welding was a labor-intensive process that required skilled craftsmen, and it was prone to human error. However, with the advent of robotic welding applications, welding processes have been completely revolutionized, and automation has become a game-changer.

Robotic welding is an automated process that utilizes robots to perform welding tasks. Welding robots are pre-programmed to follow specific welding paths, and they use a variety of welding techniques such as arc welding or resistance welding. There are many benefits to utilizing robotic welding, including cost savings, improved quality, and increased efficiency. Additionally, robotics welding applications are more reliable, safer and they can operate 24/7 without stopping.

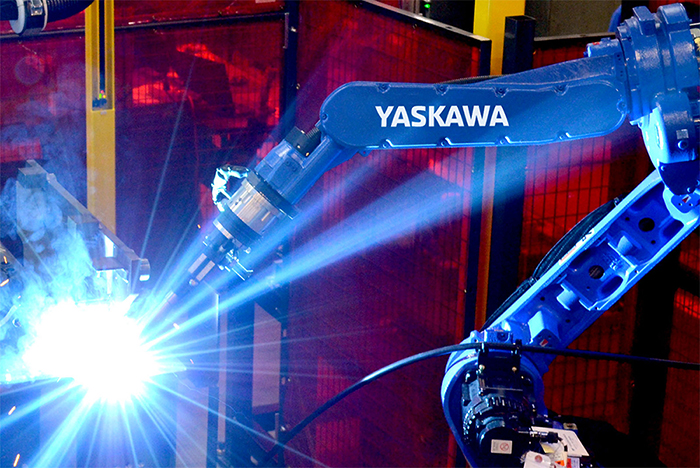

When it comes to robotic welding applications, the Yaskawa Motoman MA1440 series stands out. This six-axis MA1440 arc welding robot features a 6 kg payload, up from 3 kg on the MA1400 model. Additionally, compared to the MA1400, the new MA1440 features a 23% larger wrist hole for utilities and is up to 15% faster. The MA1440 robot is introduced with the new DX200 robot controller which is more energy-efficient and designed for improved maintainability.

This advanced robotic welding technology provides incredible accuracy, efficiency and versatility. The MA1440 series can accurately weld components found in the automotive, aerospace, agriculture, and construction industries, among others. Highly adaptable, the MA1440 robot can be easily customized to meet specific customer requirements.

Automated welding technology has been critical in improving the quality of welding processes. Robotic welding applications have eliminated the human errors that were previously common with traditional welding, such as missed welding or porosity defects in the welded joints.

Robotic welding applications can perform repetitive welding jobs faster and more accurately, resulting in more efficiency and improved cost savings. Furthermore, robotic welding can operate 24/7 non-stop, which translates into greater throughput and reduced labor costs.

Robotic welding applications are also proving to be an excellent tool for welding components in dangerous or unhealthy environments. Welding robots can easily weld in hazardous places such as high-altitude sites, under water, and in radioactive areas. This means that welding can be safely done without exposing human workers to the dangers of such environments.

In conclusion, Robotic welding technology has positively transformed the welding industry in recent years. With the development of advanced robotic welding applications such as Yaskawa Motoman MA1440, the future of the welding industry looks bright. Robotic welding has revolutionized the way welding is done, delivering precision, efficiency, and safety, and helping industrial businesses grow.

Whether you are in the automotive, aerospace, agricultural, or construction industry, adopting robotic welding is the key to staying ahead of the competition. The cost savings, quality improvements, and enhanced efficiency will help you take your welding processes to the next level, enabling you to deliver exceptional results to your customers.