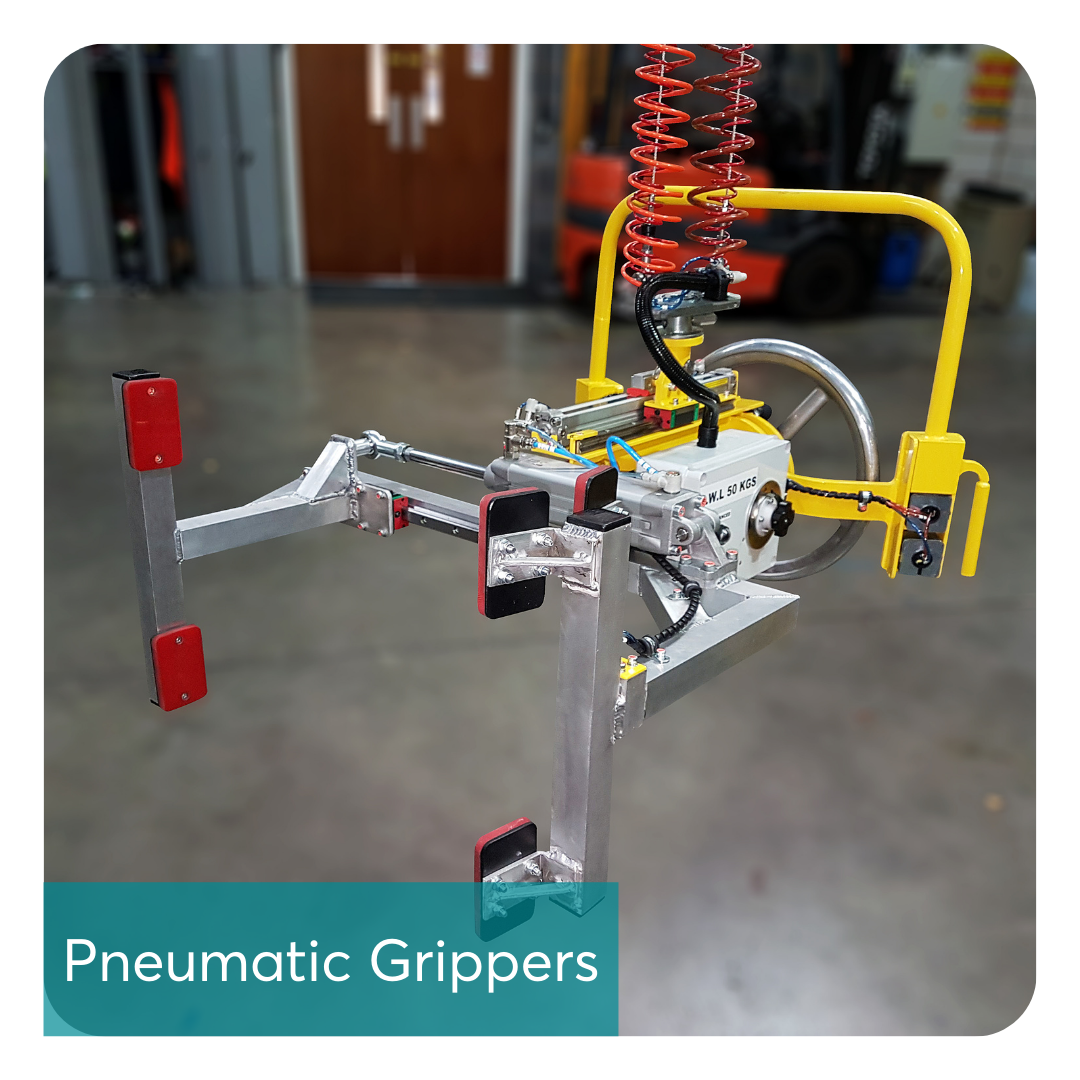

Pneumatic Gripper - The Versatile Tool

In the world of manufacturing, there are various tools and equipment that play a crucial role in the entire process. One such tool is the pneumatic gripper. It might sound like a complicated machine, but in essence, it is a relatively simple tool that has become a staple in many manufacturing units.

A pneumatic gripper is a type of pneumatic actuator that uses either parallel or angular motion to grip an object. This actuator runs on compressed air and is often combined with other components such as electric or hydraulic components. By doing so, it forms part of the "pick and place" system, allowing the component to be picked up and moved to another location in the manufacturing process.

Pneumatic grippers come in different types, including electric and hydraulic grippers. Let's take a closer look at each of these.

Electric Gripper

An electric gripper uses an electric motor to generate motion instead of compressed air. It is often used in applications where compressed air is not suitable or available. These grippers also offer greater precision and control when compared to pneumatic grippers.

Electric grippers are commonly used in the electronics industry and other industries where there is a need for high accuracy and sensitive handling. They are also effective in environments where contaminants such as oil or dust make compressed air unreliable.

Hydraulic Gripper

On the other hand, hydraulic grippers use a hydraulic cylinder to create motion. This type of gripper is often used in heavy-duty applications, where there is a need for powerful gripping force. The hydraulic gripper can deliver higher gripping force when compared to pneumatic and electric grippers, making it suitable for heavy-duty manufacturing applications.

Hydraulic grippers are commonly found in the aerospace and automotive industries due to the heavy-duty nature of these industries. They are also preferred in industrial applications where there is a need for high gripping force and gripping speed.

Advantages of Pneumatic Gripper

While electric and hydraulic grippers have their advantages, pneumatic grippers remain a popular choice in manufacturing applications for several reasons.

Cost-effective: Pneumatic grippers are generally more cost-effective when compared to electric and hydraulic grippers.

Easy to maintain: Pneumatic grippers are easy to maintain and can last for years with proper care.

Compact design: Pneumatic grippers have a compact design, allowing them to fit in tight spaces.

Fast operation: Pneumatic grippers can operate at high speeds, allowing for faster production rates.

Conclusion

In conclusion, the pneumatic gripper is a versatile tool that is essential in many manufacturing units. It provides a cost-effective and efficient solution for handling and moving components in the manufacturing process.

While there are different types of grippers available, including electric and hydraulic grippers, each has its own advantages and disadvantages. However, pneumatic grippers remain a popular choice due to their easy maintenance, compact design, fast operation, and cost-effectiveness.

As manufacturing becomes more advanced and complex, it is important to have the right tools and equipment to keep up with the demand. The pneumatic gripper is an essential part of this process, and its versatility makes it a reliable and efficient tool for various manufacturing applications.