In today's fast-paced world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their processes and maximize productivity. One company that is at the forefront of this movement is ChengZhou Technology, a factory that specializes in manufacturing CNC machining parts. With over 10 years of experience and a highly skilled team, ChengZhou Technology is known for its advanced manufacturing technology and innovative solutions.

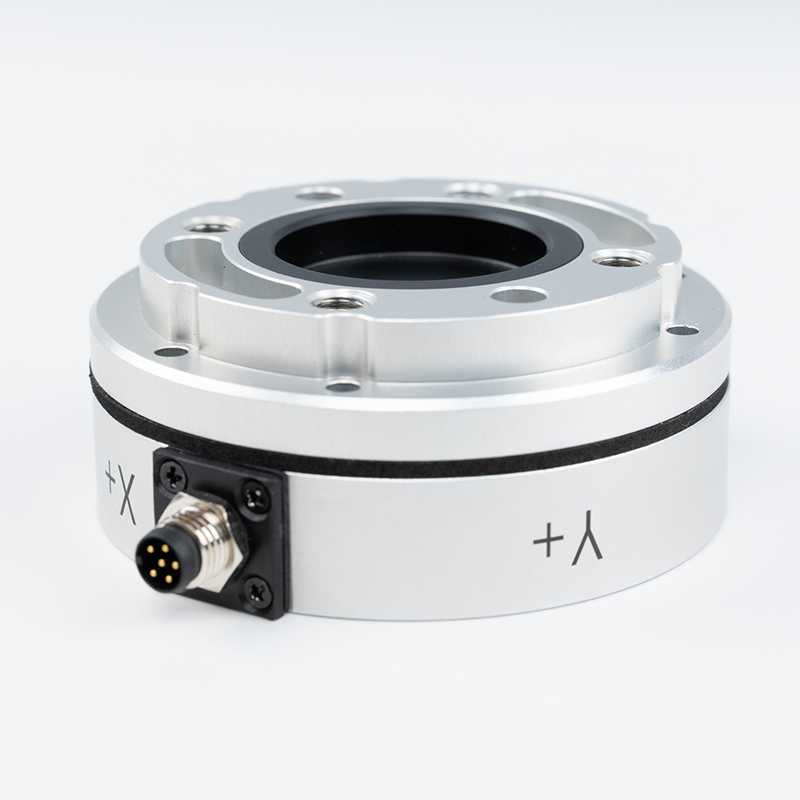

One of the latest innovations to come out of ChengZhou Technology is their automated gripper. This cutting-edge technology has the potential to revolutionize the way manufacturing processes are carried out. By automating the gripping and manipulation of parts, this new technology can significantly increase efficiency and reduce production times.

The automated gripper is a robotic tool that is designed to pick up, hold, and manipulate objects with precision and accuracy. It is equipped with sensors and actuators that allow it to adapt to different shapes and sizes of parts, making it suitable for a wide range of applications. The gripper can be programmed to perform specific tasks, such as picking up and placing parts on a production line, or sorting and organizing items in a warehouse.

One of the key advantages of the automated gripper is its ability to work 24/7 without the need for breaks or rest. This means that it can significantly increase production output, leading to higher productivity and reduced labor costs. Additionally, the gripper can handle hazardous materials or work in dangerous environments, reducing the risk of injuries to human workers.

With the implementation of the automated gripper, ChengZhou Technology has seen a significant improvement in their manufacturing processes. The gripper has allowed them to increase their production capacity and meet the growing demand for their products. It has also improved the overall quality of their output, as the gripper's precision and consistency have resulted in fewer errors and defects.

Furthermore, the automated gripper has had a positive impact on the working conditions at ChengZhou Technology. By taking over repetitive and physically demanding tasks, the gripper has relieved workers from tedious and potentially harmful activities. This has led to an increase in job satisfaction and a reduction in workplace injuries.

In addition to its benefits for ChengZhou Technology, the automated gripper has the potential to transform the manufacturing industry as a whole. As more companies adopt this technology, the entire supply chain could see improvements in efficiency and cost-effectiveness. This could lead to a more competitive manufacturing sector and contribute to economic growth.

Looking ahead, ChengZhou Technology is committed to further developing and refining their automated gripper technology. They are investing in research and development to enhance the gripper's capabilities and make it even more adaptable to different manufacturing environments. By doing so, they aim to stay at the forefront of innovation and continue to provide their customers with the most advanced manufacturing solutions.

In conclusion, ChengZhou Technology's automated gripper is a game-changer for the manufacturing industry. With its ability to improve efficiency, productivity, and working conditions, this technology has the potential to revolutionize the way products are made. As ChengZhou Technology continues to innovate and refine their automated gripper, it is clear that they are shaping the future of manufacturing.